Most all-grain beer recipes published online and in homebrew books mention brewing efficiency or brewhouse efficiency. But what is brewing efficiency and how is it measured?

Brewing efficiency is the quantity of sugar in the wort divided by the total amount of sugars which were potentially available in the grain expressed as a percentage. For example, an efficiency of 75% means that 75% of the potential sugars in the grain end up in the wort.

Once you know the efficiency of your brewing setup, you can adjust the quantity of grain in the recipe to achieve the required gravity. By increasing your brewhouse efficiency, you can potentially reduce the amount of grain needed.

Although a simple concept, there are several different efficiencies related to the brewing process, and it can get confusing. Before we go ahead and look at how to measure efficiency, let’s take a look at what brewing efficiency means.

What is brewing efficiency?

During mashing malted barley is steeped in hot water so that enzymes can convert the starch present in the barley into sugar. This creates a sugary liquid called wort which is then separated from the grains in a process called lautering. After lautering the wort is transferred to the brew kettle where it is boiled, and hops and possibly are added.

Barley manufacturers specify the amount of sugar which could potentially be extracted from their malts as extract yield. This value assumes that the maximum possible quantity of starch is extracted from the grain and converted into sugar and typically appears on the malt’s spec sheet in 3 different formats: IoB, EBC and ABC.

Brewing efficiency is the total quantity of sugar in the wort divided by the amount of potential sugar available in the grain bill expressed as a percentage.

How to measure brewing efficiency

To calculate the efficiency of your brewing setup you start by measuring the gravity of the wort when it enters the brew kettle (before it is boiled). This is called the pre-boil gravity or pre-boil OG.

Next, you convert this value into gravity points by subtracting one and then multiplying by one thousand.

For example, if your pre-boil gravity reading is 1.060, that’s 60 gravity points.

gravity points = (pre-boil gravity – 1) * 1000

After that, you need to calculate the potential gravity points in the grain bill. To do this, you multiply the extract yield of each of the malts by the amount used in kg, add them together and then divide by the volume of wort in litres.

If you are working in metric units, you should use the IoB value which is measured in litresº/kilogram. For imperial units, you can either convert this value or start with the ABV which is a percentage value.

potential gravity points = (extract yield * weight of grain in kg) / volume of wort in litres

Finally, you calculate the efficiency by dividing the wort gravity points by the potential gravity points and multiplying the result by 100 to get a percentage.

brewing efficiency = (gravity points / potential gravity points) * 100

Example efficiency calculation

The easiest way to understand this is to plug some real numbers into the calculations.

Imagine that we are making an ale using 2.25 kg of Maris Otter (extract yield 308 lº/kg) and 0.25 kg of Light Crystal Malt (extract yield 271 lº/kg) and that we ended up with 13 litres of wort in the brew kettle and a pre-boil gravity of 1.046.

First, we convert the specific gravity of the wort into gravity points.

1.046 – 1 = 0.046

0.046 * 1000 = 46 gravity points

Then we multiply the extract yield of each of the malts by the weight used.

Maris Otter: 308 * 2.25 = 693

Light Crystal Malt: 271 * 0.25 = 67.75

We add these values up and then divide by the volume of wort in litres to get the potential gravity points.

Potential points = (693 + 67.75) / 13 = 58.52

Finally, we calculate the efficiency by dividing the wort gravity points by the potential gravity points and multiplying by 100.

Brewing efficiency = (46/58.52)*100 = 78%

Alternatively, you can save time by using my brewing efficiency calculator.

Why measure brewing efficiency anyway?

By measuring the efficiency that you achieve with different recipes, you’ll get an idea of how efficient your equipment and brewing technique are.

If you find that your efficiency is significantly lower than expected, or if your efficiency varies widely from batch to batch. You may want to make some changes to your brewing technique.

How to improve brewing efficiency

Here are a few ideas which may help improve your brewing efficiency:

Mash for longer

If you find that you aren’t extracting as much sugar as expected, try mashing for longer. To check whether all of the starch has been converted into sugar, you can add iodine to a small sample of mash.

If the iodine remains brown, then you know that all the starch has turned into sugar. If it turns blue, then there is still starch present, and you should mash for longer and check that the mash is at the correct temperature.

You can find out more about mash temperatures in this post >>

Stir the mash more often

During mash in, when adding the malt, you should add the malt slowly and stir gently to prevent dough balls from forming. Dough balls prevent the enzymes from breaking down the starch.

You can also try stirring the mash every ten or fifteen minutes while mashing and then again before the vorlauf.

Recirculate and sparge for longer

The more time you spend recirculating the wort and sparging, the more of the sugar will be washed from the grist.

A slower sparge also stops the grain bed from getting too compacted and helps prevent channelling. Channelling is when the sparge water isn’t evenly distributed throughout the mash bed. When this happens, some areas of the mash bed aren’t rinsed properly.

If you brew BIAB and don’t normally sparge, you could try poring a few jugs of hot water over the bag to extract more sugar.

Eliminate dead space

Dead space in the bottom of the mash tun, pumps and pipework can mean that some of the wort doesn’t make it into the kettle. By reducing the dead space, you can improve the mash efficiency.

Mash out

Mashing out by raising the mash temperature to 77ºC (170 Fahrenheit) will help you rinse as much sugar as possible from the grain.

Mill your grain more finely

The more finely your grain is milled, the more efficiently the enzymes can get to work converting the starch into sugar. However, if the grain is ground too fine, it might cause a stuck mash.

Generally speaking, if you are brewing BIAB, you can get away with crushing your grain more finely than someone who uses a mash tun. If you don’t grind your grain, speak to the person who does and ask them to mill the grain accordingly.

Check the pH

Starch conversion works best when the pH of the mash is 5.4. You can lower the pH by adding lactic acid.

Add enzymes

During the mashing process starch from the grains is converted into sugar by enzymes called alpha-amylase and beta-amylase. These enzymes work most efficiently at temperatures between 63 and 70 ºC (145 and 158 Fahrenheit).

This process can be inhibited by adjuncts such as wheat and rice, which contain starch that isn’t soluble at temperatures below 76ºC (169 Fahrenheit). You can get around this by adding products such as Opti-Mash which contains a type of alpha-amylase that continues to convert starch into sugar at these higher temperatures.

You may also want to add enzymes if you overshoot the desired temperature for the saccharification rest.

Add DME or dextrose during the boil

If you don’t hit the pre-boil gravity, you can correct it by adding either dry malt extract or sugar to the wort during the boil.

This doesn’t actually improve your efficiency, but it’s common practice when brewing some Belgian beers and may also be necessary when brewing NEIPAs with a large amount of flaked oats in the grain bill.

Other efficiency measurements

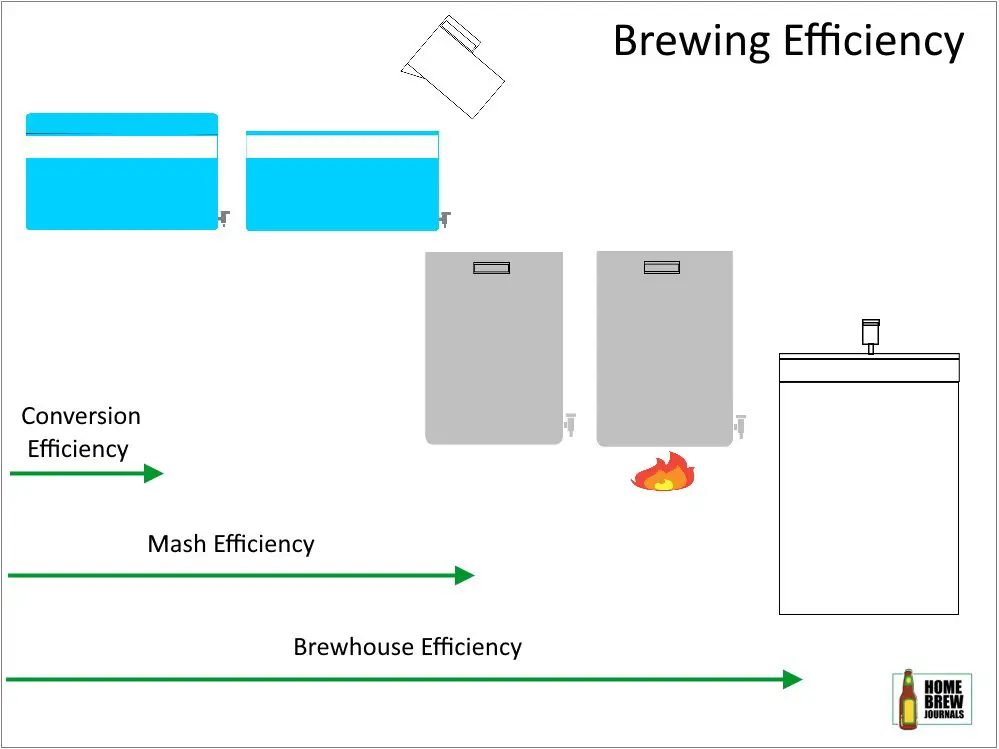

If you are familiar with brewing software such as Brewer’s Friend or Beersmith, you’ll have seen that it gives you a choice of several different brewing efficiencies.

The only difference between them is the point in the brewing process where the gravity reading used in the calculation is taken.

Mash efficiency

Mash efficiency measures the percentage of the potential sugars from the grain that are in the wort when it arrives at the brew kettle pre-boil. This is the value which most brewers are talking about when discussing brewing efficiency.

Conversion efficiency

Conversion efficiency represents how much of the potential sugar is extracted from the grain into the wort and is calculated using a sample taken from the mash. Unlike mash efficiency, it doesn’t take into account the losses during lautering and transfer to the kettle or the dead space in the mash tun.

Pre-boil efficiency

Pre-boil efficiency is the same as mash efficiency and is calculated using the pre-boil gravity reading taken from the brew kettle.

Ending kettle efficiency

Ending kettle efficiency is calculated using a sample taken after the boil has finished but before the wort is transferred to the fermenter. Unlike the pre-boil efficiency, ending kettle takes into account hop absorption and evaporation during the boil.

Brew house efficiency

Brewhouse efficiency is the percentage of the potential sugars from the grain bill, which are in the wort when it enters the fermenter. It is calculated using a gravity reading taken from the wort after it arrives in the fermenter before the yeast is pitched.

Brewhouse efficiency takes account of all the losses that occur during the brewing process.

At this point, it’s worth mentioning that some sources use the term brewhouse efficiency to refer to what we have described here as mash efficiency.