One of the most satisfying stages of homebrewing is observing the layer of krausen, which forms on top of the wort a few hours after pitching the yeast.

The presence of krausen tells you that fermentation is taking place and that, in a few days, your beer will be ready for bottling or kegging.

Like so many of the words home brewers use, the word krausen is borrowed from German and means wavy, curly or crimped. But what is krausen exactly, and what is brewing krausen made of?

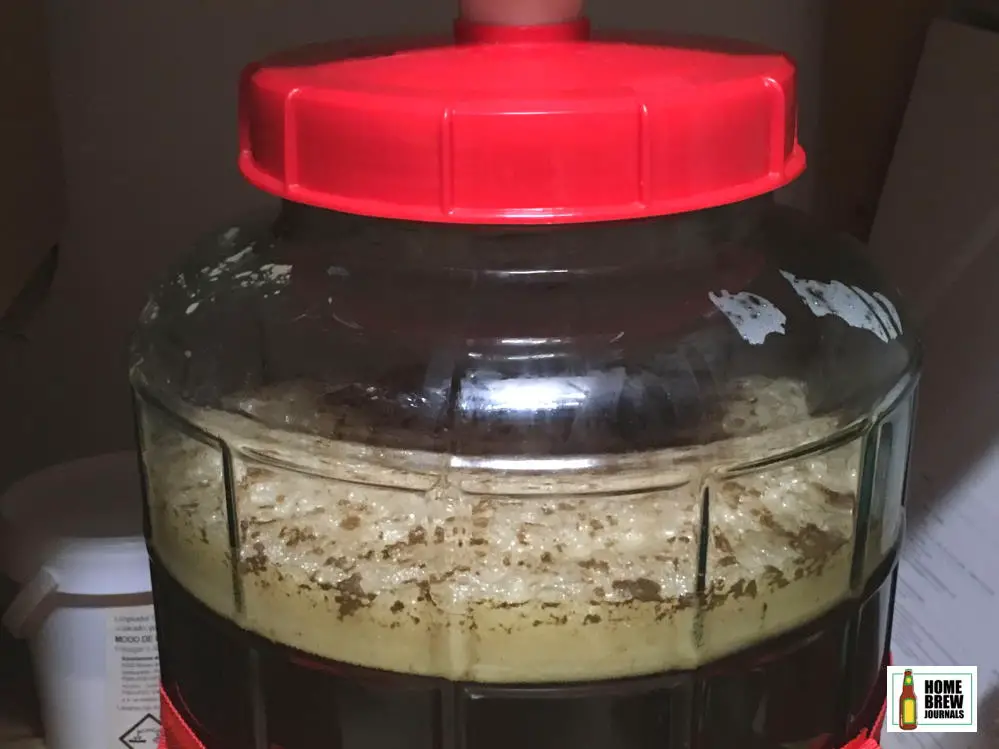

Krausen is the thick layer of foam that forms on top of wort as it ferments to become beer. The foam is made up of bubbles of carbon dioxide, protein from the wort, yeast cells, hop particles and other residues.

What is brewing krausen?

Krausen is the foamy layer that forms on top of fermenting wort.

The foam is made up of bubbles of carbon dioxide gas, protein from the wort, yeast cells, both dead and active, hop particles and other solids that may have found their way into the fermentation vessel.

Krausen is usually a pale brown or cream colour with darker streaks that can be different shades of brown or green, depending on the types of malt and quantity of hops used in the brew.

High & low krausen

Homebrewers also use the term krausen to refer to the early stages of fermentation.

After the yeast is added to the wort, it becomes active and starts to grow, breaking down fermentable sugars and producing alcohol and carbon dioxide.

The first few hours of yeast activity are referred to as low krausen. During this period, bubbles appear in the wort and rise to the surface, forming a thin layer of foam.

At this stage, the ready availability of sugars, nutrients and dissolved oxygen in the wort enable the yeast to reproduce exponentially.

As fermentation reaches its peak, usually between eight and twenty-four hours after pitching the yeast, the foamy layer becomes progressively thicker and more unruly. Brewers call this stage high krausen.

Krausen blowouts

In my article about choosing the right fermentation vessel, I told you that your carboy or brewing bucket should be approximately twenty per cent larger than the largest batch of beer that you will brew in it. This extra volume, which brewers call headspace, accommodates the layer of brewing krausen, which forms on top of the wort.

Lack of headspace in the fermenter can cause the krausen to push its way up through the airlock. When this happens, there is a good chance that the airlock will become blocked, causing the fermenter to become pressurised by the gas generated by the fermenting yeast until it blows the airlock out.

At best, this causes a sticky mess as krausen and wort shoot out over the floor, walls and even ceiling of the room or cupboard where you have stored the fermenter. At worst, glass fermenters may crack under pressure.

Both of these situations can be avoided by using a sufficiently large fermenter or by replacing the airlock with a blow-off tube during the first few days of fermentation.

A blow-off tube is simply a large diameter plastic tube that is pushed into the mouth of the carboy and runs down into a jug of either sanitiser or water. In effect, the blow-off tube and the jug of sanitiser act like an overgrown airlock, allowing carbon dioxide to escape while preventing oxygen and bacteria from entering the fermentation vessel.

The blow-off tube’s wider diameter prevents it from becoming blocked, and any excess krausen simply accumulates in the jug. Once the high krausen phase is over, you replace the tube with a standard airlock, and fermentation continues as usual.

Some brewers deliberately use a fermentation vessel with minimal headspace and then use a blow-off tube to separate the bitter-tasting krausen from the fermenting beer.

Falling or crashing krausen

As fermentation continues, yeast activity slows down, and the production of alcohol carbon dioxide decreases. As a result, the foamy layer of krausen slowly deflates, loses buoyancy and sinks to the bottom of the fermenting vessel.

As it sinks, the krausen takes the dead yeast, proteins and hop residue with it, forming a layer of sediment called trub.

At this point, homebrewers say that the krausen has fallen or crashed.

How long does high krausen last?

High krausen usually lasts somewhere between two days and one week. The exact duration depends on the style of beer being brewed, the quantity and type of yeast that was pitched and the temperature of the wort.

It’s essential to be aware that, even though the krausen has fallen and the airlock has stopped bubbling, fermentation may still be taking place, albeit more slowly than before. You shouldn’t bottle the beer until you are sure that it has reached its final gravity.

You can learn more about how to know when fermentation is complete in this post.

Kraüsening

Kraüsening is a traditional German process used to naturally carbonate beer without the addition of refined sugars or carbon dioxide gas.

When bottling or kegging the beer, instead of priming with sugar, the brewer takes a carefully calculated quantity of fermenting wort from the next batch and mixes it with the already fermented beer.

The active yeast combined with the additional sugars in the fresh wort produces more carbon dioxide, pressurising the bottles or keg ready to be served. It may also help prevent the formation of off flavours including diacetyl.

Although this method is still used by some commercial brewers, notably German brewers following the Bavarian beer purity laws or Reinheitsgebot, for the majority of homebrewers, it’s not really very practical.

Unlike the commercial brewers who brew the same beer repeatedly, most homebrewers are unlikely to have a second batch of the same beer at just the right point in the fermentation process when it comes time for bottling.