When you’re first getting into beer making it can often seem a lot like alchemy; part science, part magic and with a lot of strange words that more experienced brewers use to describe unknown and mystical procedures.

Three words that come up a lot are lautering, sparging and vorlauf. But what do they mean and more importantly, how are they done? To answer these questions, we’re going to take a step back to the start of the beer-making process.

The first step in all-grain brewing is called mashing. This is when malted barley is mixed with hot water so that enzymes present in the malt can convert starch from the grain into sugar.

Once mashing is complete, the wort is separated from the spent grain in a three-step process called lautering. Sparging is the last stage of the lautering process when the grain bed is rinsed with water to extract as much sugar as possible.

Now that we’ve defined what sparging is let’s take a look at how to do it.

How to sparge

Over the centuries, three methods of sparging have evolved:

Fly sparge

Fly sparging was invented by German breweries during the nineteenth century and is the most efficient way of extracting the maximum amount of sugar from the grain. If you’re unsure what brewing efficiency is, check out this article.

When fly sparging, you begin by recirculating the wort to filter out solids and settle the grain bed, this process is called vorlauf.

Once the wort is clear and free from particles, it is then drained into the brew kettle until just enough liquid is left to cover the grain bed. Ideally, you want there to be a couple of centimetres of wort above the top of the grain bed.

Sugar is then rinsed from the grain by slowly sprinkling water from above. The aim is not to disturb the grain while simultaneously draining the wort into the brew kettle. When done correctly, the flow should be such that the level of water remains constant.

When fly sparging, you must ensure that the grain bed doesn’t run dry otherwise cracks may form and let water through without rinsing the grains properly.

Nowadays almost all commercial brewers and quite a lot of homebrewers fly sparge.

No sparge

British breweries traditionally used the no sparge method to make several batches of beer from one mash.

When making the first batch, they would mash as usual and then just run off all the wort into the kettle. They would then refill the mash tun with hot strike water before mashing once again using the same grain as for the previous batch.

By repeating this process, the brewery was able to make three or four batches of progressively weaker beer from a given quantity of grain.

Batch sparge

Batch sparging is similar to no sparge sparging (sic) except that, instead of creating several batches, all the wort is mixed together in the brew kettle to make one batch of beer.

The technique is prevalent among home brewers due to its simplicity and the fact that it is quicker than fly sparging. Unlike commercial brewers who strive to achieve the best possible efficiency to reduce costs, most homebrewers like the simplicity of batch sparging and don’t mind spending a little more on malt.

BIAB sparging techniques

There are two ways of sparging when brewing BIAB. You can either pour jugs of water over the bag or perform a so-called dunk sparge whereby the bag is placed in a pot of hot water to rinse out the sugar.

Many BIAB brewers don’t bother sparging. Instead, they suspend the bag above the kettle while it drains and then gives it a gentle squeeze to extract as much sugar as possible.

Fun Fact:

Sparge is derived from the Latin word spargere which means “to sprinkle”.

When should you stop sparging?

If you are fly sparging, you should stop sparging either when you have collected the required amount of wort or when the specific gravity has dropped to 1.010.

If you continue sparging at lower gravities, you may start to extract tannins from the mash, giving your beer an unpleasant astringent taste. Think tea that has been left in the pot for far too long.

Correct sparge water temperature

The correct temperature for sparge water is 77ºC (170 Fahrenheit). Sugar is more easily dissolved in hot water, so sparging at this temperature helps extract the maximum amount of sugar from the grain bed.

Using sparge water which is hotter than 77ºC (170) will extract tannins from the grain, causing astringency as mentioned above.

What’s the difference between sparging and lautering?

Lautering is the process of separating the wort from the grain and is usually done in three steps: mashout, recirculation (vorlauf) and sparging. Sparging is the last step of lautering when the remaining sugars are rinsed from the grain.

Is sparging in beer making really necessary?

As mentioned above, BIAB brewers and people brewing high gravity ale recipes, often choose not to sparge. However, this does lower the brewing efficiency, meaning that more malt is needed to create the same quantity of beer.

If you are making beer using an extract beer kit then sparging has already been done for you. Extract homebrew kits contain a can or packet of concentrated wort which you dilute and then boil before adding the hops.

What equipment is needed for sparging?

The equipment needed for sparging depends on which method you are using.

The beauty of batch sparging is that you don’t need any additional equipment whatsoever. Most homebrewers, open the spigot of the mash tun and drain the wort directly into a plastic fermentation bucket. They then add hot water to the mash from the brew kettle. Finally, the wort is combined in the brew kettle and heated up in preparation for the next stage in the beer-making process.

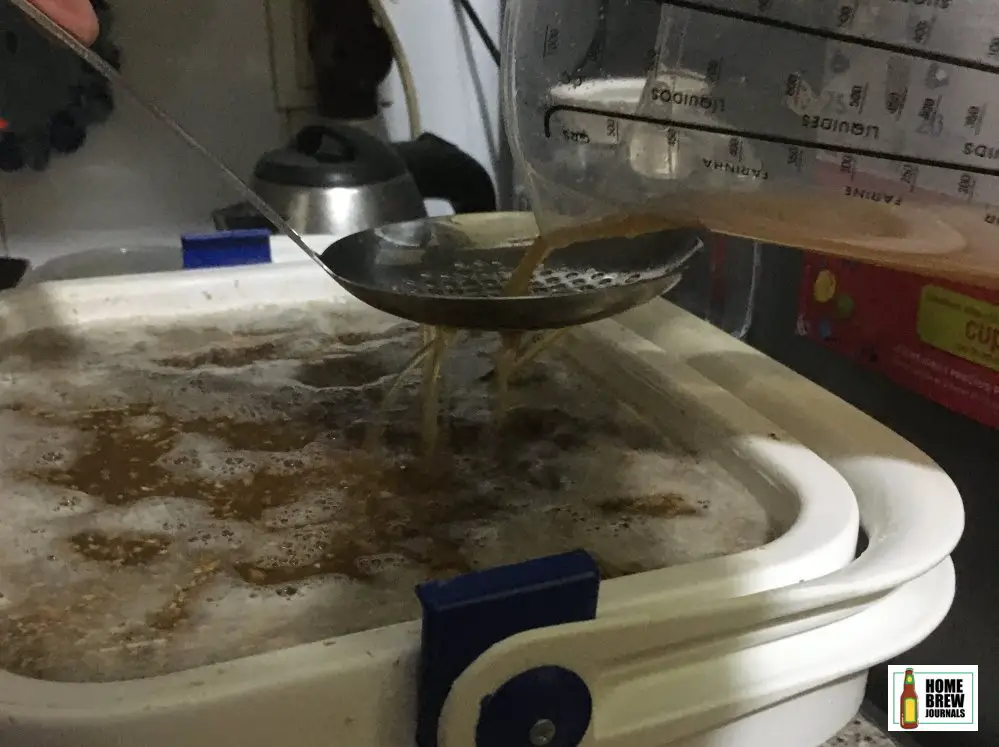

If you decide to fly sparge, you will probably want to purchase a stainless steel sparge arm. Personally speaking, I brew small 10 litre batches and fly sparge by slowly pouring water from a plastic jug over a large steel skimmer spoon, as shown in the photo above.

When brewing BIAB, you’ll need to find a way to support the bag of grain as it drains into the kettle. For small batches, you can just set the bag on a colander or sieve placed on top of the kettle. Once it has drained you then place the bag in a large bowl and pour a couple of litres (quarts) of hot water over it.

For larger batches, you may have to rig something up to support the bag while it drains. In his excellent book Brew, which is available to download from Amazon, James Morton explains how he rigs up a system using an aluminium step ladder.

What is a stuck sparge?

During the sparging process, the grain bed acts as a filter which prevents the manifold in the bottom of the mash tun becoming blocked. A stuck sparge is when liquid is unable to flow through the grain bed.

A stuck sparge is most likely to happen if you are using rolled oats or wheat, both of which contain high levels of beta-glucanase that can gum up the mash. If your recipe calls of a large quantity of rolled oats, it’s a good idea to mix rice hulls in with the grain to help it drain correctly.