If you’re new to home brewing, the chances are you’ve got a lot of questions that need to be answered before getting started.

One of the first questions that most new brewers ask is how long do you brew beer?

It usually takes between four and six weeks to brew beer. Most of the activity takes place on day one, which is when the wort is prepared. After this, you should allow two weeks for fermentation followed by a further two to four weeks of conditioning, either in bottles or a keg.

The exact time needed depends on the style of beer you are brewing.

When brewing ales, you should allow approximately two weeks for fermentation to occur before transferring the beer to either a keg or bottles. Once bottled, ales (bitter, IPA, stout, etc.) take about two weeks to become carbonated and clear.

Lagers generally take an extra two to four weeks to fully mature. After fermentation has completed, the beer is transferred to a secondary vessel and stored in a cold place. This process is called laagering and gives the beer its typical clarity and crisp taste.

Some speciality beers can take even longer to brew. For example, sour beers undergo several fermentation stages, each of which may last several weeks.

How long do you brew beer?

Day One – brew day

As I said at the start of this post, most of the work done by a homebrewer takes place on day one, aka brew day. Exactly how long this takes largely depends on whether you are brewing all-grain or from an extract kit.

The term all-grain brewing means that you begin by soaking malted barley in hot water to extract the sugar. You then separate the grain from the sugary liquid, which is called wort. Next, the wort is boiled, and hops are added. You then boil the wort for an hour before cooling it down and transferring it to the fermentation vessel, where yeast is added, and fermentation takes place.

There are several ways of doing this and, depending on what equipment you have, it usually takes around six hours.

Extract kits contain pre-made wort, which you mix with water in the fermentation vessel before adding the yeast. This simplifies the brew day and reduces how long it takes to around half an hour.

Most experienced homebrewers prefer to brew all-grain because it allows them to control what their finished beer tastes like. For new brewers, extract kits like this one sold on Amazon are a great way to get started and produce good tasting beer.

Sanitation

Sanitation is one of the most important aspects of home brewing and shouldn’t be overlooked when calculation how long it takes to brew beer.

It’s absolutely essential that you sanitise everything which comes into contact with your beer after the wort has finished boiling.

On brew day, you must sanitise the wort chiller, fermentation vessel, airlock, hydrometer and any tubes and spoons which may come into contact with the wort.

Once fermentation has completed, it’s essential that you thoroughly sanitise your auto-siphon, bottles, crown caps and keg. Missing this critical step can result in otherwise good beer being spoiled.

No-rinse sanitisers such as Star san take just a few minutes to sanitise everything. I usually mix about ten litres of sanitiser in a large washing up bowl. I then leave all my equipment to soak until just before it’s used.

Fermentation

Once the wort has cooled to the correct temperature, generally between 18 and 22 ºC (65 to 71 degrees Fahrenheit), it can be transferred to the fermentation vessel.

The wort then needs to be aerated to introduce oxygen. This typically takes about ten minutes.

Once the yeast has been added to the wort, fermentation takes place in four stages. Exactly how long each step takes will vary depending on the type of yeast used, whether you made a yeast starter and the temperature at which fermentation occurs.

- Lag Phase

- Exponential Fermentation Phase (High Krausen)

- Static Fermentation Phase

- Conditioning

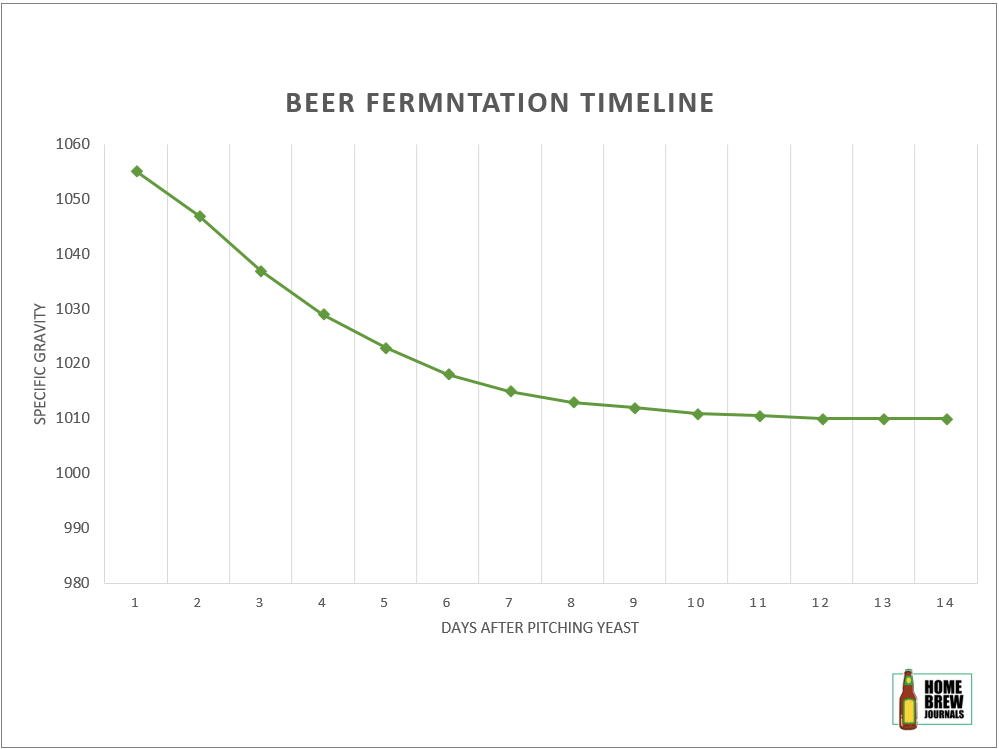

Beer Fermentation Time Chart

1. Lag Phase

The lag phase is the time between when the yeast is added to the wort (pitched) and when active fermentation starts to take place.

There will be no bubbles in the airlock during this period, and it might look like nothing is happening. But in fact, the yeast is busy absorbing oxygen and nutrients from the wort and is starting to grow and multiply in numbers.

The lag phase typically lasts from eight to twenty-four hours and can be reduced by using liquid yeast and preparing a yeast starter.

2. Exponential Fermentation Phase

Once the lag phase is over, the yeast starts consuming sugar from the wort, creating alcohol and carbon dioxide.

At this point, the yeast multiplies rapidly; a thick layer of foam known as Krausen forms on top of the wort, and the airlock bubbles vigorously.

The exponential fermentation phase typically lasts between one and four days. During this period, the specific gravity drops rapidly as the sugar in the wort is consumed by the yeast.

3. Static Fermentation Phase

Once the exponential phase is over, the rate of yeast growth slows down. At this stage, the specific gravity drops more slowly, the layer of krausen on top of the wort drops down, and only the occasional bubble is seen in the airlock. Sometimes the airlock may stop bubbling entirely at this stage.

During the static fermentation phase, the yeast stops creating alcohol and starts cleaning up after itself, reabsorbing the unwanted byproducts produced during the exponential fermentation phase. The yeast begins to flocculate, clump together and sink to the bottom of the fermentation vessel.

This phase typically takes between three and ten days, during which time, after the airlock stops bubbling, you should take gravity readings to determine when fermentation has finished.

4. Conditioning Phase

Once fermentation has finished, the yeast and other sediment continue to sink to the bottom of the fermentation vessel. At this stage, you should be taking a gravity reading every two days until you get two successive readings that are the same. Indicating that fermentation is complete.

Bottling or Kegging

Once fermentation has completed, it’s time to bottle or keg the beer. Bottling is the other stage of the home brewing process when the brewer actively does things.

First, the bottles or keg plus, crown caps, auto-siphon, bottling wand, priming spoons and any other miscellaneous items which may come into contact with the beer need to be meticulously sanitised to prevent the beer from becoming infected by unwanted bacteria.

If you use a plastic fermenter, you can bottle the beer directly from the spigot. Before doing so, you should sanitise the faucet by spraying sanitiser from a plastic spray bottle. You should also take care that none of the spent yeast and other sediments (trub) is transferred to the bottles.

You should also try to minimise splashing during the bottling process, which can introduce oxygen into the beer, causing it to taste like wet cardboard.

I usually brew ten-litre batches of beer, and it normally takes me approximately two hours to clean, drain, prime and fill the bottles.

Bottle Conditioning

The freshly bottled beer should now be left in a cool dark place for at least two weeks before drinking. During this period, the yeast left in suspension in the beer uses up the priming sugar, which was added when the beer was bottled, releasing carbon dioxide, which carbonates the beer.

Once the reactivated beer has consumed all the priming sugar, it sinks to the bottom of the bottle. The beer becomes clearer and develops its final flavour.

Although ales are ready to drink after two weeks of bottle conditioning, I usually find that most styles of beer taste even better after four weeks.

Conclusions

It usually takes me four weeks to brew beer. This is broken down into four stages; brew day, fermentation, bottling and bottle conditioning.

Some types of craft beer, including lagers, Lambic, and Trappist beers may take considerably longer.

Commercial breweries, and some homebrewers, use special techniques to speed up the brewing process.