Once you’ve pitched the yeast, it’s time to move the fermenter to a dark place and fit the airlock. Between eight and twelve hours later, carbon dioxide should start bubbling out through the airlock, indicating that fermentation is taking place.

This brings us to the age-old homebrewer’s question of how much water should I put in the airlock. The answer to this question depends on the type of airlock you are using.

Most airlocks have a mark which indicates the correct fill level. S-shaped airlocks should be filled one-third of the way up. Three-piece airlocks should be filled halfway. As long as there’s enough water to prevent air from entering the fermenter, the exact level isn’t critical.

In this post, we take a look at why an airlock is necessary, how airlocks work, how much water and other common airlock related questions.

Why is an airlock needed?

During the fermentation and conditioning process, your homebrew is vulnerable to two things; bacterial infection and oxygen. Since both bacteria and oxygen are present in the air, the fermenter must be sealed to stop air from getting in.

However, if the fermenter was totally sealed, it would quickly become pressurised by the carbon dioxide generated during fermentation and could rupture or explode.

To prevent this from happening a device called an airlock (sometimes called a fermentation lock) is fitted to the fermenter. The airlock allows carbon dioxide to escape while, at the same time, preventing air from getting in.

How does an airlock work?

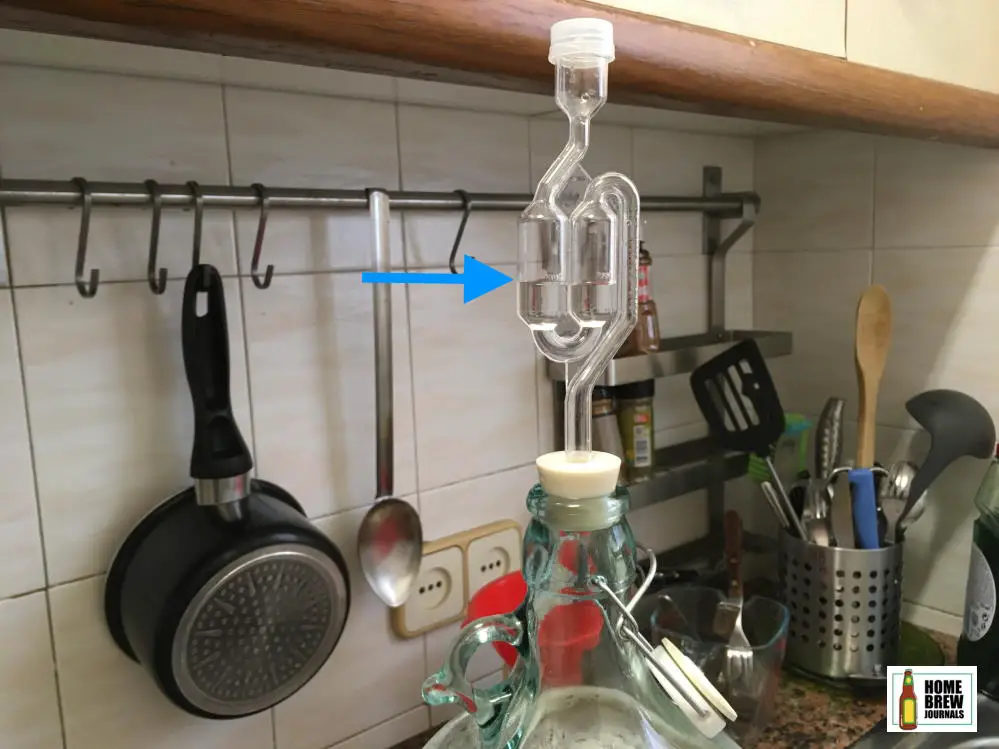

There are two types of water-filled airlocks available; S-shaped airlocks and 3-piece airlocks. Both kinds of airlock work by creating a water trap which forms a barrier between your beer and the outside world.

Carbon dioxide released during fermentation pressurises the fermenter slightly. As the pressure increases, bubbles of CO2 push past the water in the airlock and escape, equalising the pressure.

Since the pressure inside the fermenter is always slightly higher than ambient pressure, carbon dioxide can escape, but air can’t get in. The water also prevents bugs and dust from finding their way into the fermenter.

By the time that fermentation is over, the empty space in the fermenter is full of carbon dioxide which is trapped by the airlock. At this point, the airlock serves to equalise pressure differences caused by changes in ambient temperature.

How much water should I put in a homebrew airlock?

S-shaped airlocks

Traditional S-shaped airlocks have either one or three bulbs on either side of the S-bend. As pressure develops inside the fermenter, the water in the airlock gets pushed round to one side of the airlock until finally a bubble of can escape.

After the bubble of gas has escaped, the water equalises on both sides of the S-bend, and the process starts over again.

If your airlock has three bulbs on each side, you should add enough water so that the bottom bulb is full. If it has one bulb on each side, you should fill it one-third of the way up the bulbs.

Three piece airlocks

Three-piece airlocks have a central tube which is covered by a plastic cowl. As pressure builds up inside the fermenter, the cowl lifts up, allowing a bubble of gas to escape through the water in the outer chamber.

You should fill a three-piece airlock approximately halfway up with water.

The advantage of three-piece airlocks is that they can be taken apart for cleaning and are less prone to getting blocked with krausen during periods of very active fermentation.

What should I fill the airlock with?

Up until now, we’ve spoken about putting water in the airlock.

Although water is an effective barrier against germs, dust and bugs, many homebrewers, myself included, fill the airlock with sanitiser (Star San etc.). The advantage of using sanitiser instead of water is that it eliminates the risk of infection if some of the liquid gets sucked into the beer.

Another popular alternative to water is vodka or other high proof alcohol. Once again, the idea is that it reduces the risk of infection if some of the liquid gets sucked into the fermenter. If you decide to use alcohol, you should avoid methanol or rubbing alcohol, both of which are toxic.

What will happen if I underfill or overfill the airlock?

The exact quantity that you put in the airlock isn’t too critical. As long as there is enough water in the airlock to create a barrier to airflow, the airlock will still work.

If you put too much water in the airlock, some of it will be expelled when carbon dioxide starts bubbling out from the fermenter. Once the excess water has been pushed out, the airlock will function as usual.

Should I put the cap on the airlock?

Most airlocks come with a plastic cap to stop dust and insects from getting inside. Once you have filled the airlock with water or sanitising fluid, you should gently push the cap into place. Small holes or ridges on the cap allow gas to escape but stop bugs and dirt from getting in.

Do I need to fit an airlock to the secondary fermenter?

Even though fermentation has stopped, an airlock is still needed during secondary fermentation and conditioning. Carbon dioxide continues to be released from the beer for several days. The airlock also compensates for pressure differences caused by changes in the ambient temperature.

If your beer or wine will be conditioning for an extended period, you should check the airlock regularly to ensure that the water hasn’t evaporated and top it up if necessary.

Common airlock related problems

You should check the airlock regularly during the fermentation and conditioning process. Here are some common airlock related problems and how to fix them.

No water in the airlock

If for some reason you find that there is no water in the airlock, or the level is too low to make an effective barrier, you should quickly remove it from the fermenter and top it up to the correct level before refitting.

Airlock full of krausen

During the fermentation process, a layer of foam called krausen forms on top of the wort. If fermentation is especially vigorous, or if there isn’t enough headspace in the fermentation vessel, some of the wort may get pushed out through the airlock.

If this happens, you should remove the airlock and thoroughly clean and sanitise it. Once the airlock has been sanitised, top it up to the correct level with sanitising fluid before fitting it to the fermenter.

It’s a good idea to keep a couple of spare airlocks handy so that you can quickly swap them out if needed.

Airlock blown out

If the airlock becomes full of krausen, there’s a chance that it will become blocked and get blown out of the top of the fermenter. If this happens, you should quickly replace it with a spare airlock, adequately filled with water.

Unsure what size of fermenter you need? Take a look at this post >>

Airlock not bubbling

Bubbles of carbon dioxide should start to flow through the airlock between eight and twenty-four hours after you pitched the yeast.

Don’t worry if the airlock doesn’t start bubbling; this doesn’t necessarily mean that fermentation hasn’t begun. If you are using a plastic fermentation bucket, there’s a good chance that the lid doesn’t seal correctly and that gas is leaking out elsewhere.

If this happens, you should wait two weeks before taking a gravity reading. If the specific gravity is as expected, then fermentation has taken place. Even though the fermenter has a slight leak, carbon dioxide is heavier than air and fills the empty space, protecting against infection and oxidation.

Airlock alternatives

Although most homebrewers use either an S-shaped or three-piece airlock, there are several alternatives available.

Blow-off tube

A blow-off tube is effectively an overgrown airlock.

In the early stages of fermentation, krausen may get forced up into the airlock, causing it to get blown out. This is especially likely if you are fermenting in a glass carboy since there isn’t as much surface area as in a fermentation bucket.

To stop this from happening, you can replace the airlock with a length of wide diameter plastic tube. One end of the tube fits snugly into the mouth of the carboy. The other end is then submerged in a jug of sanitiser.

Silicon bungs

Another interesting alternative which I’ve yet to try is the waterless airlock. These are silicon rubber bungs with multiple narrow holes drilled in them covered by a flap. The idea is that the flap will open to let carbon dioxide escape but won’t let air enter the fermenter.

Balloons and other improvised airlocks

When I was researching this post, I came across a couple of quirky DIY alternatives to the standard water-filled airlocks.

Some people claimed to have achieved good results by stretching a balloon over the mouth of their carboy and fixing it with rubber bands. They then pricked holes in the balloon to let CO2 escape.

Other people spoke of covering the opening with a piece of sanitised aluminium foil.

To be honest, proper airlocks are so cheap that I don’t see why you’d want to risk spoiling a batch of beer just to save a few pennies.